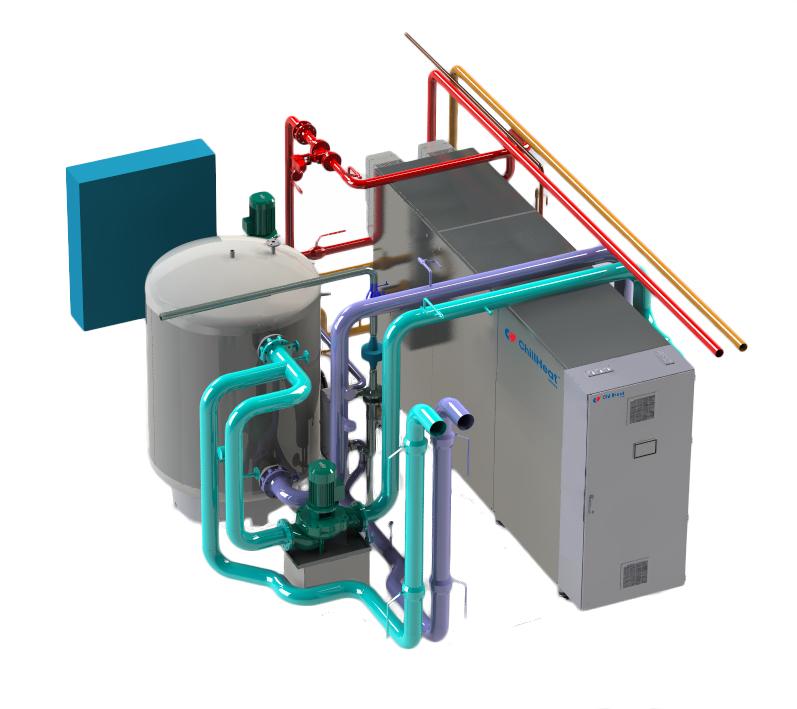

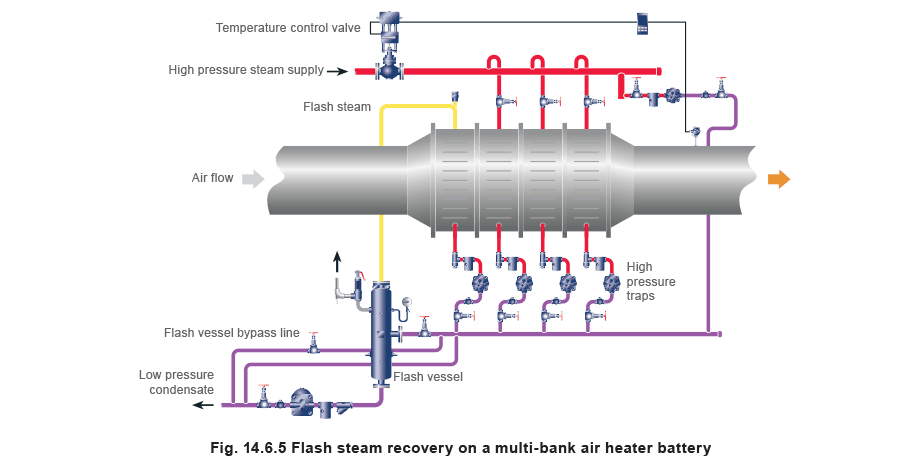

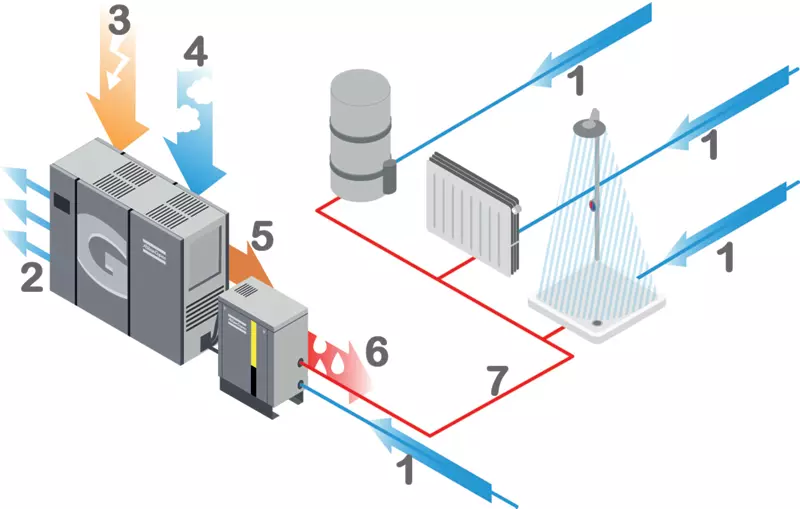

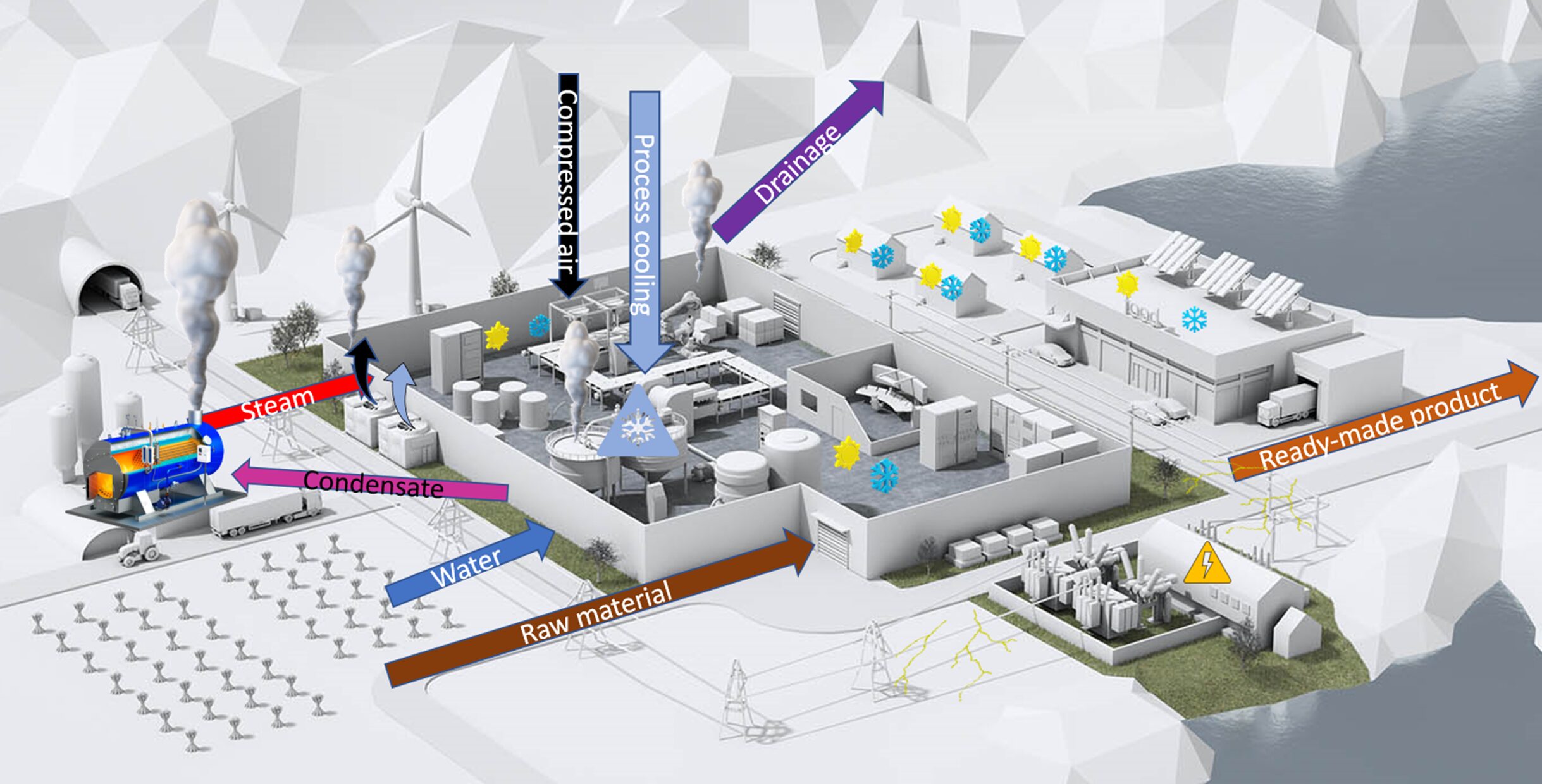

By capturing and reusing waste heat or energy from various processes, our solutions increase overall energy efficiency, reduce operational costs, and minimize environmental impact. These solutions are particularly valuable in energy-intensive industries systems where substantial energy savings and emissions reductions can be achieved. Energy recovery can ba simple 1 heat exchanger solution or a complex sector-coupling system.

-

Economical

Ensure a positive impact on your bottom line through reduced operational expenses

-

Improved efficiency

Enhance operational efficiency and optimize resource utilization by reusing waste heat or energy

-

Ecological

Minimize the carbon footprint and support eco-friendly practices

-

Regulatory compliance

Adhere to stringent environmental regulations, ensuring compliance

-

Smart energy solutions

Our energy recovery solutions represent smart and adaptive approaches to energy management